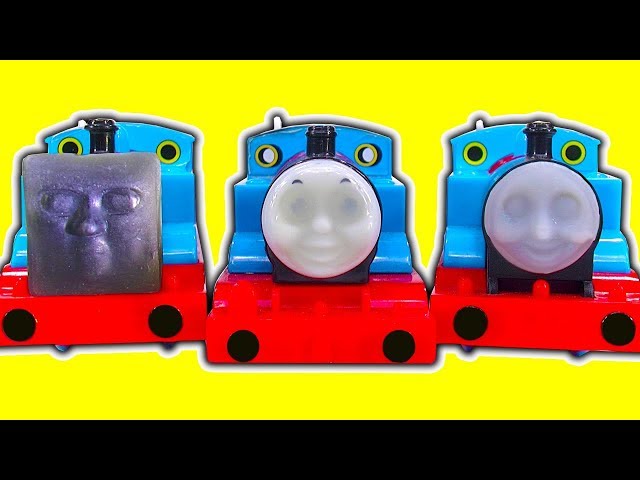

How to make clone Thomas Tank character face's using three different methods. After playing with a UV setting plastic resin I show a way to build up a Thomas face that's easy to work with and robust. Maybe the very simple idea in all this is using Blu Tac as a way to get an impression of Thomas character faces. This is just a hard and fast DIY way while trying to use everyday materials. I also use Hot Melt glue and more traditional moulding agents. My curiosity about the UV setting plastic called Bondic started this adventure. Another YouTuber who I know (M3sca1) found a source company who made 3D resins for 3D printers. This product is not too expensive and it's curious to play with. What triggers it to turn plastic is UV light. The sun will also set this resin to solid in no time. But I find the little UV light on the Bondic or 5 sec fix product is ample enough to do these small faces. Anyway maybe from my playing around you have some ideas to make simple duplicates of Thomas Toy faces without getting too complicated. Note the Monocure 3D resin I use is the rapid setting resin. It's normal use is via 3D printers to make highly detailed and intricate models. My use of the product is a weird reverse engineering method thats pretty fast.

A photopolymer or light-activated resin is a polymer that changes its properties when exposed to light, often in the ultraviolet or visible region of the electromagnetic spectrum. These changes are often manifested structurally, for example hardening of the material occurs as a result of cross-linking when exposed to light. An example is shown below depicting a mixture of monomers, oligomers, and photoinitiators that conform into a hardened polymeric material through a process called curing. A wide variety of technologically useful applications rely on photopolymers, for example some enamels and varnishes depend on photopolymer formulation for proper hardening upon exposure to light. In some instances, an enamel can cure in a fraction of a second when exposed to light, as opposed to thermally cured enamels which can require half an hour or longer. Curable materials are widely used for medical, printing, and photoresist technologies.

Web Links :

http://www.monocure3d.com.au/default.asp

http://www.monocure3d.com.au/category...

https://en.wikipedia.org/wiki/Blu_Tack

https://en.wikipedia.org/wiki/Hot-mel...

https://en.wikipedia.org/wiki/3D_prin...

https://en.wikipedia.org/wiki/Photopo...

Thomas The Tank Face Duplicator How To Monocure 3D Resin Fast & Simple ─ leokimvideo

<style>.embed-container { position: relative; padding-bottom: 56.25%; height: 0; overflow: hidden; max-width: 100%; } .embed-container iframe, .embed-container object, .embed-container embed { position: absolute; top: 0; left: 0; width: 100%; height: 100%; }</style><div class="embed-container"><iframe src="https://www.youtube.com/embed/OTlsewgnGXc" frameborder="0" allowfullscreen></iframe></div>